View Dry Ice cleaning Round Rock in a full screen map

https://www.atomicautospa.com/blog/how-dry-ice-cleaning-can-transform-engine-bay-detailing

| Entity | Definition |

|---|---|

| Engine Bay Dry Ice Cleaning | A technique used to clean vehicle engine bays using dry ice without water or chemicals. |

| Undercarriage Dry Ice Cleaning | Dry ice blasting method used to remove grime and rust from a car’s undercarriage. |

| Interior Dry Ice Detailing | A method of using dry ice to deep clean and restore a vehicle’s interior components. |

| Classic Car Dry Ice Restoration | A restoration process that uses dry ice cleaning to preserve classic car parts without damage. |

| Dry Ice Cleaning for Wheels | A cleaning technique that removes brake dust, road grime, and debris from wheels and rims. |

Revolutionary Dry Ice Cleaning for Cars

Atomic Auto Spa leads the way in advanced car care with dry ice cleaning, a powerful yet delicate method for removing dirt, grease, and contaminants without water or harsh chemicals. This eco-friendly, non-abrasive process is perfect for high-performance vehicles, classic cars, and everyday vehicles that require precision cleaning without damage.

Dry ice cleaning is effective for engines and undercarriages, as it removes grime without moisture buildup. It is safe on all surfaces, leaving no residue or abrasion. It is also ideal for vehicle restorations, keeping original finishes intact while providing a thorough clean.

For those who demand flawless results with zero risk, dry ice blasting is the ultimate solution.

Protect your investment by contacting Atomic Auto Spa today for expert dry ice cleaning.

Atomic Auto Spa

3401 Sunrise Rd. Suite 210 Round Rock, Tx 78665

512.888.9310

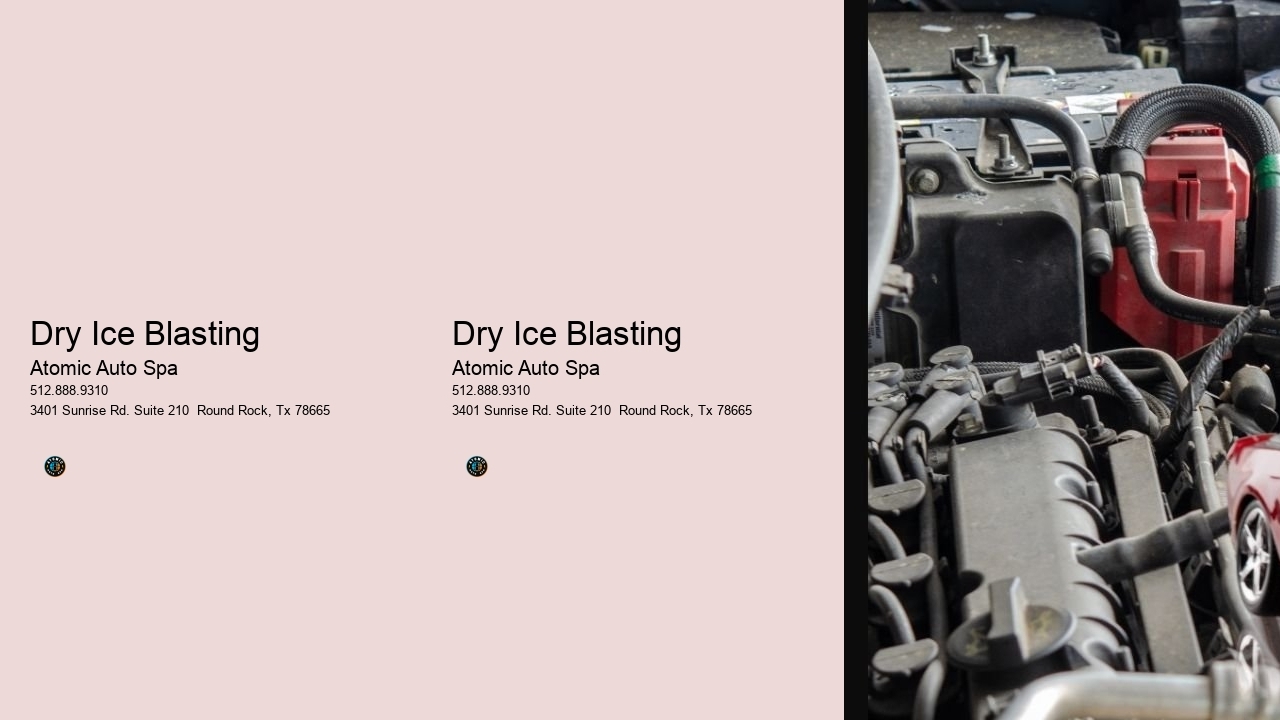

Dry ice cleaning, also known as dry ice blasting, is an innovative cleaning process that utilizes solid carbon dioxide (CO2) pellets. These pellets are propelled at high speeds towards the surface being cleaned through specialized blasting equipment. Upon impact, the dry ice sublimates—turning directly from a solid to a gas—lifting dirt and contaminants without leaving any water or chemical residue. This non-abrasive method avoids damage to delicate parts and doesn't contribute to corrosion.

The adoption of dry ice cleaning has gained significant traction among automotive enthusiasts due to its effectiveness in maintaining and restoring vehicles. Particularly valuable for classic car restoration or high-performance vehicles where precision is crucial, it allows for thorough cleaning of engine compartments, undercarriages, and other components without disassembly. The appeal lies in its ability to preserve original parts and paint finishes while offering a level of cleanliness that traditional methods often cannot achieve. As a result, it's becoming an essential tool for those preparing their cars for shows or safeguarding their investment with Paint Protection Film (PPF) applications.

Dry ice cleaning harnesses the sublimation process of dry ice—solid carbon dioxide (CO2)—which transitions directly from a solid to a gas without passing through a liquid state. This unique property is pivotal because it means no moisture is introduced to the automotive parts during cleaning, preventing rust or electrical issues. As pellets of dry ice are propelled at high speeds toward dirty surfaces, they absorb heat upon impact and rapidly sublimate. This instantaneous conversion requires energy, which leads to the embrittlement and lifting of contaminants.

Automotive enthusiasts favor dry ice blasting due to its non-abrasive nature; unlike sandblasting or chemical cleaners, it doesn't damage the substrate material, preserving the integrity of vintage components and delicate surfaces such as those with paint protection film (PPF). The absence of secondary waste streams also appeals to environmentally conscious users. After sublimation, only the dislodged dirt remains to be swept away, making cleanup minimal and avoiding chemical disposal concerns while providing a thorough clean that's both eco-friendly and effective for vehicle maintenance.

Dry ice cleaning harnesses the power of carbon dioxide pellets, which are blasted at high speeds onto automotive surfaces. These pellets are extremely cold, with temperatures around -78.5 degrees Celsius (-109.3 degrees Fahrenheit), making them highly effective at loosening grime and contaminants.

The process of sublimation is central to dry ice cleaning's effectiveness. Upon contact with a surface, the solid CO2 pellets instantly change from a solid state to a gaseous state without passing through a liquid phase. This transformation results in a micro-explosion that dislodges dirt and debris.

This method is particularly valued for its precision and ability to clean without abrasion. As there's no granular waste material left behind, it’s gentle on delicate car parts and doesn't damage paint or finishes like traditional sandblasting might.

The absence of chemical residues post-cleaning ensures that vehicles not only look pristine but also remain free from potentially harmful substances. This aspect makes dry ice cleaning a preferred option for prepping surfaces before applying protective paint films (PPF) or other coatings.

Finally, automotive enthusiasts appreciate the environmental aspect of dry ice cleaning; as CO2 used in this process often comes from recycled sources, and the gas simply evaporates into the atmosphere after use, leaving minimal impact on the environment compared to conventional methods involving harsh chemicals or extensive water usage.

Dry ice cleaning, a method embraced by automotive enthusiasts, stands out particularly for its ability to meticulously clean vehicles without abrasion. This technique utilizes solid CO2 pellets that sublimate upon contact, meaning they turn directly from a solid to a gas, lifting dirt and contaminants away without leaving moisture behind. It's an ideal match for maintaining a car's paint protection film (PPF), which acts as a barrier against scratches, stone chips, and environmental elements. Dry ice cleaning ensures the PPF remains intact and effective by avoiding the scratching or peeling that can occur with traditional cleaning methods. Moreover, it reaches into nooks and crannies that are often missed by conventional tools, preserving not just the vehicle's appearance but also its functionality by preventing build-up in hard-to-reach areas like engine components and undercarriage parts. The non-toxic nature of dry ice also means there are no chemical residues left on the vehicle or in the environment, making it a preferred choice for those committed to eco-friendly practices.

Dry ice cleaning is a godsend for automotive enthusiasts who prioritize the pristine condition of their vehicles. This innovative technique uses solid CO2 pellets that sublimate upon contact, meaning they turn directly from solid to gas without leaving any residue. Unlike traditional methods, dry ice blasting doesn't scratch or harm surfaces, ensuring the original finish and intricate designs remain unscathed.

The absence of water in dry ice cleaning offers a significant advantage when dealing with sensitive components. Traditional washing methods introduce moisture that can lead to corrosion or electrical issues over time. Dry ice's moisture-free process eliminates this risk, providing peace of mind for car owners who demand meticulous care for every part of their vehicle.

Moreover, since dry ice cleaning foregoes the use of harsh chemicals, it's an environmentally friendly option that aligns with the values of those passionate about eco-conscious detailing. It avoids introducing chemical pollutants into the environment and prevents exposure to potentially harmful substances for both the detailer and the vehicle owner.

Delicate parts and electronics in cars require careful handling to avoid costly damages. Dry ice cleaning stands out because it gently removes dirt and grime without physical contact, preserving these components' functionality and aesthetics. This level of preservation is especially critical for classic or high-performance vehicles where originality and condition are paramount.

Finally, by maintaining delicate parts through non-abrasive cleaning, dry ice contributes to prolonging a vehicle's life span. Enthusiasts who invest in paint protection films (PPF) find that dry ice cleaning complements their efforts by not damaging these protective layers while ensuring thorough cleanliness—a harmonious blend between maintaining appearance and safeguarding long-term integrity.

Dry ice cleaning has become the go-to solution for automotive enthusiasts looking to meticulously restore classic cars. Its non-abrasive nature ensures that even the most delicate surfaces are treated without damage, effectively removing contaminants like dirt, grease, and old undercoating from a variety of materials including metal, plastic, and rubber. This precision is particularly valuable in preserving original parts that contribute to a vehicle's historical authenticity and overall value.

In regular maintenance routines, dry ice blasting plays a pivotal role in decontaminating engine compartments and other mechanical areas with speed and efficiency. It allows for thorough cleaning without the need to dismantle components, saving time and reducing the risk of damaging sensitive electronics or intricate parts. Moreover, as it leaves no secondary waste—sublimating upon contact—it aligns perfectly with PPF (paint protection film) care by keeping underlying surfaces pristine and ready for protective film application or reapplication.

Dry ice cleaning has revolutionized the way automotive enthusiasts approach the meticulous care and restoration of classic cars. This non-abrasive method is particularly favored for its ability to effectively remove contaminants such as dirt, grease, and oil from engine components without causing damage to the parts or surrounding materials. Car enthusiasts often utilize dry ice cleaning to rejuvenate undercarriage areas, which are notorious for accumulating grime and rust that can be challenging to clean with traditional methods. Additionally, when preparing a vehicle for paint protection film (PPF) application, dry ice blasting ensures a pristine surface by stripping away any old adhesive residues or waxes that could compromise the adhesion and finish of the PPF. The precision of dry ice cleaning allows for detailed work on intricate parts like carburetors, wiring harnesses, and heat shields—restoring them to a condition that resembles factory-new without disassembly. In essence, this innovative technique provides car buffs with an efficient tool for preserving the performance and aesthetic appeal of their cherished autos while safeguarding their value over time.

Conventional automotive cleaning techniques, such as sandblasting, solvents, and wire brushes, can be abrasive and often harm delicate components. These methods may leave behind residues or result in wear and tear over time. Especially when preparing a vehicle for paint protection film (PPF) application, the surface needs to be immaculate and undamaged to ensure proper adhesion.

Dry ice cleaning stands out with its non-abrasive nature that eliminates the risk of damaging surfaces. This method uses frozen CO2 pellets that sublimate upon contact, lifting dirt and contaminants away without leaving any secondary waste. It is particularly effective for intricate parts where precision is crucial.

Compared to traditional methods that often require chemicals or generate hazardous waste, dry ice cleaning is environmentally friendly. It doesn't produce toxic runoffs or airborne particles, making it safer for both the user and the environment. This aspect aligns well with the meticulous care required before PPF applications where cleanliness is paramount.

While initial setup costs for dry ice cleaning may be higher than some traditional methods, it proves more cost-effective in the long run due to its low impact on vehicle parts leading to less frequent repairs or replacements. For automotive enthusiasts investing in PPF, preserving their car's condition while ensuring a pristine surface for film application adds invaluable longevity and aesthetic appeal to their vehicles.

Conventional cleaning methods such as sandblasting, steam cleaning, and the use of chemical solvents carry various safety concerns. Sandblasting can produce harmful dust and requires extensive protective gear, while steam cleaning poses risks of burns and may damage sensitive components with its high temperatures. Chemical solvents often involve toxic substances that require careful handling and disposal. In contrast, dry ice blasting is a non-toxic method that eliminates the risk of chemical exposure and minimizes physical hazards. It uses solid CO2 pellets that sublimate upon contact, leaving no residue behind.

The environmental footprint of traditional cleaning techniques can be significant. Sandblasting generates waste in the form of used abrasive materials which must be disposed of properly to prevent contamination. The use of chemical solvents contributes to VOC emissions and potential groundwater pollution if not managed correctly. Steam cleaning consumes large quantities of water, with wastewater requiring treatment before release into sewage systems. Dry ice blasting stands out for its eco-friendliness; it produces no secondary waste since dry ice sublimates directly into gas, thus eliminating the need for waste disposal associated with other media.

When comparing the effectiveness of different cleaning methods, each has its advantages depending on the application. Sandblasting is powerful for removing stubborn coatings but can roughen or warp surfaces if not used with care. Steam cleaning is effective for sanitization but may not be aggressive enough for heavy build-up removal. Chemical cleaners can target specific contaminants effectively but might harm underlying materials or paintwork over time. Conversely, dry ice blasting offers precision cleaning without abrasiveness, preserving original surfaces — an aspect particularly appreciated in automotive PPF (paint protection film) maintenance where maintaining finish quality is paramount.

Automotive enthusiasts are raving about the precision and cleanliness that dry ice cleaning offers. One user highlighted how this method effortlessly removed years of grime from his classic car's engine bay without damaging any electrical components. The process was not only thorough but also preserved the integrity of sensitive parts, something traditional cleaning methods struggled with.

For those passionate about maintaining their vehicle's value, dry ice cleaning is a game-changer. A proud owner of a vintage sports car shared her experience saying that after dry ice treatment, her vehicle looked like it had rolled off the assembly line, even in the most overlooked nooks and crannies. This level of detail contributes to higher valuations and better preservation of automotive history.

Prior to applying paint protection film (PPF), ensuring a spotless surface is essential for optimal adhesion. Enthusiasts have found that dry ice cleaning creates the perfect canvas for PPF application by stripping away all contaminants. One customer noted that since he started using dry ice before PPF installation on his luxury sedan, he has noticed a significant improvement in both the film’s appearance and longevity.

Environmentally conscious car lovers appreciate that dry ice blasting is a non-toxic and eco-friendly way to clean their vehicles. Instead of relying on harsh chemicals, one environmentally-minded enthusiast was pleased to discover that he could achieve superior results while also protecting nature – an aspect becoming increasingly important within the community.

The efficiency of dry ice cleaning has become another frequently mentioned benefit among car aficionados. A dedicated hobbyist explained how switching to this method reduced his detailing time significantly without compromising on quality – allowing him more time behind the wheel and less time with a scrub brush in hand.

Car enthusiasts often seek the most effective methods to maintain their vehicles in pristine condition. Dry ice cleaning has emerged as a revolutionary technique among owners, especially those preparing their cars for paint protection film (PPF) applications. They recount how this method meticulously cleans even the most challenging parts without leaving a residue, preparing the surface optimally for PPF adherence.

One of the most lauded benefits from users is dry ice cleaning's non-abrasive nature. Traditional methods risk damaging original components or leaving moisture behind. But after adopting dry ice cleaning, car owners marvel at the ability to preserve delicate electronics and vintage parts while achieving a deep clean—something especially valued in classic restorations where authenticity is paramount.

The before-and-after scenarios have been particularly telling for skeptics turned advocates. Owners share images of engines covered in decades of grime that are restored to near-factory finish, with no sign of wear from cleaning. The stark contrast not only showcases the effectiveness but also translates into better performance and longevity of mechanical parts.

Finally, automotive aficionados recognize an indirect financial advantage: enhanced resale value. By using dry ice cleaning, they ensure their vehicles are spotless and well-maintained down to the finest detail—a fact not lost on prospective buyers. Car enthusiasts find that this investment pays dividends when it comes time to sell or trade-in their cherished rides.

Dry ice blasting is a non-abrasive cleaning method that uses solid CO2 pellets or ice particles to clean surfaces. This technique is especially useful for cars with paint protection film (PPF) as it effectively removes contaminants without damaging the film. Unlike traditional water-based methods, dry ice blasting doesn't leave behind any residue, making it an ideal choice for preserving your vehicle's appearance.

For vehicles equipped with PPF, maintaining the cleanliness of the car not only contributes to its aesthetic appeal but also helps in prolonging the life of the protective film. Dry ice blasting can be instrumental in this process because it cleans without compromising the integrity of PPF. It can remove tough grime and debris that regular washing might miss, ensuring that your car’s protective layer continues to shield the paint from scratches, chips, and UV damage.

The frequency with which you should employ dry ice blasting on your car depends on various factors such as driving conditions, exposure to pollutants, and personal preference for vehicle cleanliness. For those who drive regularly in urban or industrial environments where cars are more likely to accumulate dirt and pollutants quickly, considering a dry ice cleaning every three to six months could be beneficial. However, if your driving conditions are less demanding or if your car sees less frequent use, a semi-annual or even annual cleaning may suffice.

While dry ice blasting is often more costly than traditional car wash options due to its specialized equipment and process, many owners of high-end vehicles find value in this investment because of its effectiveness and safety on PPF. By avoiding abrasion and potential damage from conventional cleaning methods, you save money in the long run by extending the life of your car’s PPF and thereby protecting your vehicle's resale value.

Not all auto detailers offer dry ice blasting due to its niche nature; therefore finding a reputable service provider is crucial when considering this cleaning method for your vehicle. Look for professionals who have experience working with vehicles covered by PPF and who understand how dry ice blasting interacts with different types of protective films. Proper technique will ensure that your investment in both the cleaning service and the PPF itself will yield maximum benefits over time.

Costs range from $300-$1,500+ depending on the level of service.

Grease, oil, paint, adhesives, carbon buildup, and biological contaminants.

Yes, it is safe for electrical parts as it does not use moisture.